By Barry Redican, Showerbuddy

Manufacturing in China has shaped the global market for decades. For companies in the medical device space like Showerbuddy, China has been central to how we create high quality products at prices that remain accessible for users and families. There is a growing conversation in parts of the world about bringing manufacturing “back home”. In the USA especially, this idea is gaining traction again. But from where I sit, after twenty years of building and maintaining a manufacturing operation in China, that belief simply does not match the reality.

Why companies came to China in the first place

The honest answer is cost. The efficiency, scale, supply chain integration, and production excellence in China are remarkable, but the primary driver for Western companies has always been cost. When the shift began decades ago, manufacturers in the USA, New Zealand, Australia, and across Europe were searching for a way to produce goods at a price point their markets could sustain. China provided that. And consumers benefitted enormously.

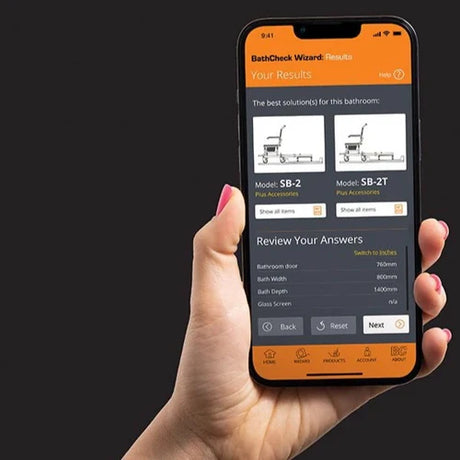

Showerbuddy is one of thousands of medical device companies that manufacture in China. The lower manufacturing costs meant we could bring clever, well built mobility solutions to families who otherwise would not be able to afford them. It supported innovation and made accessibility equipment far more reachable for everyday people.

Over time, costs in China have risen. As the local population has become wealthier and factories improved conditions and standards, that has naturally flowed through to pricing. The factories we work with today are worlds apart from those I first visited two decades back. But the system remains far more cost efficient than anything that could realistically be replicated in most Western markets.

The idea of returning manufacturing home

There is an illusion circulating in political circles that returning manufacturing to the USA is easy or even likely. In my view, it is an anomaly in thinking. Manufacturing left Western countries for a very simple reason. It was too expensive to stay. Shifting factories back will not magically reverse the economics that have shaped global trade for the past thirty to forty years.

Some argue tariffs will force companies to return production onshore. Tariffs sound powerful in theory, but in practice, the cost simply passes down the line. The importer pays first, then eventually the consumer does. Even when tariffs are applied to broad categories of imports, medical devices are typically exempt, just as they were during COVID because of their essential nature. But imagine tariffs did apply. The only outcome is higher prices for households.

Importers may temporarily absorb some of the cost by accepting lower margins, and Chinese factories may negotiate small reductions to maintain the relationship. But neither side can sustain that forever. Sooner or later, the full impact shows up at the retail level.

When local manufacturers in the USA see their overseas competitors’ prices lifting due to tariffs, they naturally begin raising prices too. That is exactly how the market behaves.

I remember this pattern well from New Zealand in the 1960s. Buying a New Zealand made car required almost a lifetime of saving. When imports from Japan opened, prices fell dramatically. The American market has enjoyed that same pattern for decades through imports from China. Reversing that now will simply push prices up on everything from mobility devices to everyday goods.

The reality of building manufacturing capability in China

Manufacturing in China is not easy, and no one should think otherwise. It takes years to establish the level of trust, reliability, and quality control needed to produce consistently at scale.

When you first arrive as a foreign company, you are a risk. You are asking a local supplier to build low volume runs of a product they have never made before, with no history of payment or partnership. There is scepticism on both sides. Early volumes are tiny compared to what Chinese factories normally handle. No one is rushing to supply you until trust is built.

Showerbuddy lived through this. We moved between two factories in the early days because quality and timeliness simply were not where they needed to be. It took time to establish consistency, and the only solution was building a long term partnership with the right factory.

That takes five to eight years. Not months. Years.

You must visit, regularly. You must pay on time, every time. You must show you are here for the long haul. For me personally, I am in China every two or three months, spending a week here at a time. I spend time with the team, the factory owner, and his family. These relationships matter, because this is what allows a foreign company to get the service, pricing, and reliability they need.

Why on the ground presence is essential

One of the great misconceptions about manufacturing in China is that you can manage everything from afar. In reality, the only way to make it work is to have your own people on the ground.

For Showerbuddy, our on site engineering manager is absolutely pivotal to our success. This is not a low cost role. This person is paid at a level equivalent to a CEO. That is the value of having a trusted expert ensuring quality, process, and timelines are met in person.

As our volume and product range have grown, we have added a second full time on site manager. Both work inside the factory every day. Without that, we would not have the supply chain reliability or product quality our customers rely on.

It is expensive to do it properly. It takes persistence, cultural understanding, and long term commitment. But it delivers extraordinary value once established.

Will the USA or other Western markets bring manufacturing home?

I doubt it. Not at any meaningful scale.

The infrastructure, labour market, supply chain systems, and cost structures needed to recreate what China has built over decades are enormous. The only way local manufacturing becomes competitive is if imported products become so expensive that households simply accept higher prices across the board.

That is not a recipe for economic success, and it is certainly not good for consumers of essential medical equipment.

Western companies moved manufacturing to China because it made sense. It still makes sense today. The world has benefitted from the affordability it created. And while China has evolved, modernised and become more expensive than it once was, it remains the most effective global system for producing high quality, specialised products at scale.

For those of us who have spent years building deep, reliable relationships here, the value is clear. The real savings are definitely there, but they come only after the hard yards have been put in.

And that is why, despite the political noise, manufacturing in China remains central to how Showerbuddy delivers world class solutions to users around the world.

![Toilet Training A Young Child With Mobility Challenges [And How A Shower Chair Can Help]](http://shower-buddy.com/cdn/shop/articles/toilet-training-disabled-child_520x500_a90e5234-d372-435d-aa56-8da15dd3836c.webp?v=1722557239&width=460)